9 Aug 2023

10 Essential Safety Tips Every Scaffolder Should Follow

In the world of construction, the margin between safety and disaster can be as thin as the scaffolding that towers above the ground. It's a world where the winds of risk blow as strongly as those at dizzying heights. Yet, amidst these challenges, scaffolders stand tall, armed with expertise and caution, ensuring the skyline continues to grow without compromising on safety. Among the many tools and protocols they adhere to, one digital ally stands out: Scafflinq, the Digital Scafftag Management application. Here are ten essential safety tips every scaffolder should follow, with a special emphasis on how Scafflinq is revolutionizing scaffold inspections.

1. Get Trained Properly

Before stepping onto a scaffold, ensure you're trained by accredited professionals. Understanding the nuances of scaffold erection, dismantling, and alteration is crucial. Depending on which region of the world you operate in there are different legal requirements, for instance in Australia, scaffolds over 4.0 metres in height must be erected and dismantled by a ticketed scaffolder.

2. Wear Personal Protective Equipment (PPE)

Always wear appropriate PPE, including hard hats, non-slip boots, and harnesses when required. This gear is your first line of defense against potential hazards. Follow your Safe Work Method Statement or Job Safety Analysis for more specific requirements for your job. If you’re unsure, always check with your Supervisor or Manager.

3. Inspect the Scaffold Before Use

Never use a scaffold without inspecting it first. Look for signs of damage, instability, or missing parts. This is where Scafflinq shines, offering a streamlined approach to Scaffold Inspections.

4. Maintain a Clean Workspace

Keep the scaffold free of debris and tools that could pose tripping hazards. A tidy workspace not only ensures safety but also enhances efficiency. This also applies to the ground area where scaffolding will be stacked during a dismantle. Remove any trip hazards from your work area.

5. Know and follow Load Capacities

Adhere strictly to the scaffold's load capacity. Overloading can lead to structural failure, putting everyone at risk. Keep this in mind when stacking material during the installation and dismantle process. Sometimes, you may require more hands in the chain to keep material moving and not store it on the decks.

6. Ensure Stable Foundation

Always ensure the scaffold is on stable ground. Use base plates and mud sills if necessary to prevent sinking or shifting. Request a geotechnical report from your client to ensure the ground has the correct bearing capacity. If you are installing scaffolding on a roof, ensure the roof is designed to take the loads of the scaffold in addition to the workers and materials on the scaffold. An engineer may have to design the scaffolding structure and baclpropping structure. Scafflinq can keep track of the Duty Categories of scaffolding so your clients are aware of the safe work limits.

7. Use Guardrails and Fall Protection

For scaffolds over 2 metres, guardrails and fall protection systems are a must. These barriers can be the difference between a safe day at work and a catastrophic fall. Always follow your Safe Work Method Statement. Working at heights is a High-Risk activity and should only be undertaken by trained a competent professionals.

8. Avoid Working in Bad Weather

High winds, rain, and lightning can turn scaffolding into a dangerous place. If conditions worsen, descend and wait for the weather to clear.

9. Communicate Effectively

Always communicate with your team. Use hand signals or radios to ensure everyone is aware of operations and movements on and around the scaffold. Setup exclusion zones underneath your work area and communicate this with barricades and signage so other trades do not enter the work area.

10. Regular Scaffold Inspections

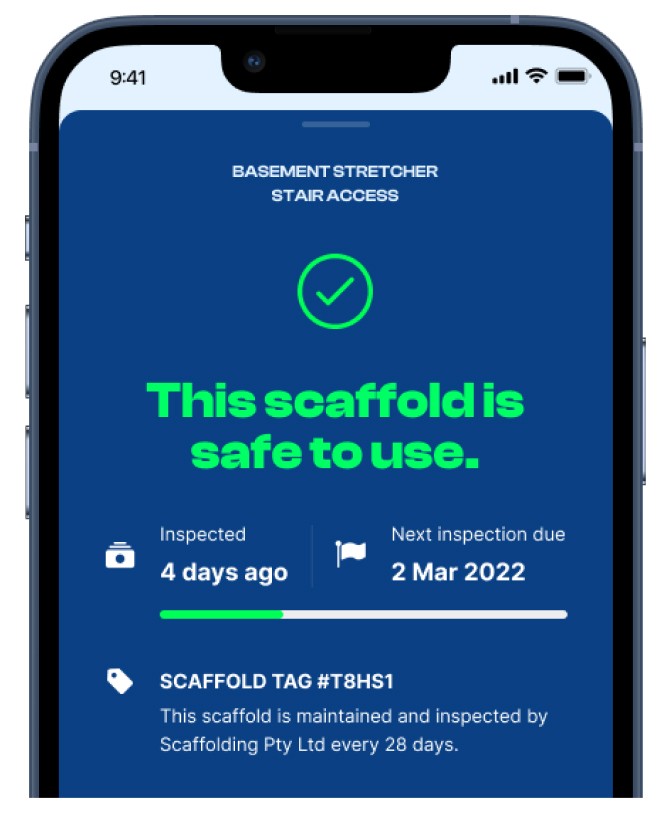

Conducting scaffold inspections every 28 days is not just good practice—it's a regulatory requirement. This periodic check ensures the integrity and safety of the scaffold over time. Enter Scafflinq, the all-in-one platform for Scaffold Inspections. Available on Google Play and the App Store, Scafflinq serves as a digital bridge connecting the onsite scaffolders with the office, ensuring that every Scafftag is digitally logged, inspected, and managed. With Scafflinq, inspections are no longer a cumbersome task but a streamlined process that ensures compliance and safety without compromising on efficiency.

Scafflinq is designed to keep pace with the dynamic demands of modern construction sites. It not only aids in meeting the crucial 28-day inspection requirement but also transforms the management of Scafftags into a digital, foolproof system. By integrating Scafflinq into their workflow, scaffolders, safety managers, and construction leaders can elevate their safety protocols to new heights. Digital Scafftags provide an unprecedented level of transparency and accountability, making Scafflinq an indispensable tool for anyone serious about scaffold safety.

The Bottom Line

In the high-stakes world of scaffolding, safety is not just a guideline—it's a lifeline. By adhering to these ten essential safety tips, scaffolders can safeguard themselves and their teams against the myriad risks presented by working at heights. With the introduction of Scafflinq, the process of ensuring scaffold safety is now more accessible, efficient, and reliable than ever. This digital revolution in scaffold inspections represents a significant step forward in our collective commitment to creating safer construction environments. Let's embrace this technology and continue to build our future on the foundation of safety and excellence.